News posted on: 2017/9/20 7:42:39 - by yoyo - RFIDtagworld XMINNOV RFID Tag Manufacturer

It is an important measure that equipment daily inspection work is the guarantee of equipment running smoothly, maintenance or inspection is a more time-sensitive work, requiring duty officers must periodically check every inspection point. But the manual inspection, it is difficult to effectively monitor the duty inspectors, resulting in frequent inspection report is not in place, failure to deal with the various types of accidents caused by failure; In addition, the paper inspection can not pass real-time inspection data, which will leading to failure not timely, affecting the safe and efficient operation of various types of equipment.

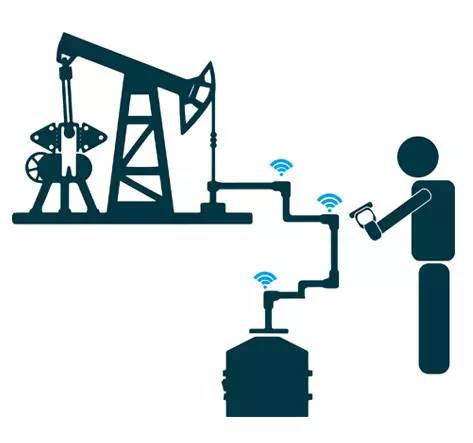

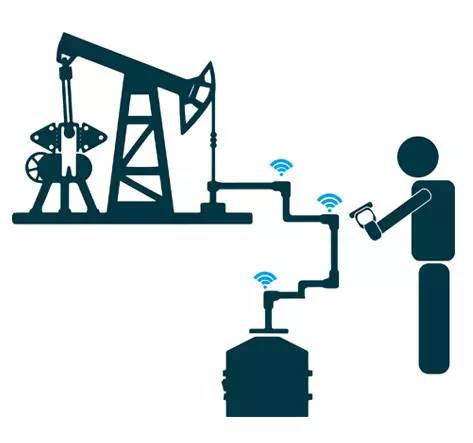

射频识别技术和无线局域网设备的使用ent and pipeline inspection, usually used in power, manufacturing enterprise equipment inspection, petrochemical pipeline inspection and so on. In the factory area along the inspection route covered seamless wireless network, in each inspection monitoring point to install a RIFD label, the label records the basic information of the inspection site. Inspection staff every time a patrol point first read the contents of the label with a handheld device, check the equipment and pipelines, the test information transmitted through the wireless network to the management office. The backstage establishes a patrol management system, through the system to achieve the inspection of the quality of inspection work to improve the level of inspection equipment, improve inspection efficiency, insight into the inspection work.

Oil refinery equipment and pipeline inspection refers to the equipment security department of its equipment, pipelines for regular inspection, inspection, to ensure the safety of oil transportation and refining. For a long time the refinery inspection work has been in use "a table system" work. Inspection personnel in accordance with the inspection route inspection equipment and pipelines, and then select the operation on the form, return to the management of statistical inspection situation. As the inspectors are not strong sense of responsibility, weather conditions and other factors, and sometimes inspectors lazy, false investigation patrol situation, making the quality of security inspection greatly reduced.

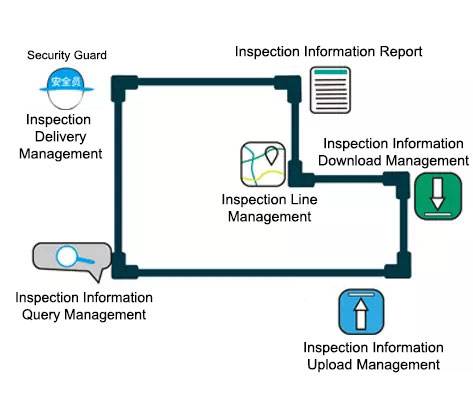

Based on RFID technology equipment maintenance & daily inspection system mainly includes inspection delivery management, inspection line management, inspection information download management, inspection information upload management, inspection information query management, inspection information report management etc. Hardware devices are mainly composed of RFID handheld terminals and RFID tags, wireless access points. In this system design, closely around the core needs of the industry and inspection operations of key business processes, and closely integrated RFID technology in the practical needs of the applicability, such as the choice of electronic tags using ultra-high frequency passive electronic Tag, the corresponding reading distance should be larger, so as to accurately detect the electronic tag information.

Inspection business operation process

(1) in the existing inspection site placement RFID tags, labels are initialized, record the basic information of inspection points, such as inspection number, inspection location;

(2) the establishment of inspection and management information system, through the system of business management, in the system practice the inspection business operations, management, statistics, analysis;

(3) when the inspection plan will be planned to enter the system, such as inspectors, inspection routes, departure time, requirements, etc., and then the inspection task sent to the RFID handheld reader, and then inspectors set off;

(4) inspection personnel in accordance with the inspection task began to patrol, at the detection point of the RFID reader near the inspection inspection site, can automatically record the detection of personnel detection;

(5) inspection of the situation and the results can be real-time through the wireless LAN network to the management information system can also be returned to the management center will be the inspection data uploaded to the management information system;

(6) management center can be managed through the management system to check the completion of the inspection plan, you can query, print the appropriate inspection statistics.

Patrol/Petrol equipment system fully utilized the physical advantages of RFID technology, the main use of ultra-high frequency RFID without contact, reading distance characteristics, without manual intervention, thus improving the convenience of inspection staff inspection, greatly reducing the inspection the workload of the staff.Long reading distance can achieve long-distance data acquisition, better to achieve long-distance equipment inspection; RFID recognition speed, reducing the number of inspection time, improve efficiency and improve the management level of equipment inspection; RFID technology can be appropriate penetrate the cloth, skin, wood to read, and be able to fully cope with the harsh environment of the challenge to maintain all-weather work.

The important is that RFID technology brings real-time and accuracy of data, enabling managers to gain insight into the data and transforming that insight into a best practice for business management, improving management and forecasting capabilities, Efficiency and management.

Case - Sinopec Oilfield Asset Intelligent Management Project

The oil field belongs to the industry with complicated operation process and harsh production environment, and the equipment type and quantity of the oil field are running normally. At present, the vast majority of the domestic oil field using manual recording and bar code or laser marking combination of asset identification and management, but the manual management is inevitable mistakes, over time, the original information is easy to lose. According to reliable statistics, the annual cost of oil in the asset management to reach billions of dollars, because the existing management is not suitable for oil harsh complex harsh operating environment, assets exposed to the outside, in addition to the need to withstand sun and rain, these assets are often affected by high temperature, chemicals, oil, pressure and impact and other factors, bar code and laser marking can not afford such a harsh environment, only industrial-grade UHF RFID solutions to meet the oil field The application of the environment.

The oil field plans in the next few years, most of its anti-spray wells, oil pipelines and other related assets for all RFID applications, the first implementation of a type of asset pilot applications. The main purpose of the application is through the installation of RFID tags on assets, through a specially developed software system to record the assets from the purchase to use, throughout the service period all the important information, including: asset procurement time, the person in charge, the supplier Information and price; the use of assets, maintenance and repair, inventory records; assets of the regular inspection records, the person in charge of information and so on. More importantly, RFID technology for the staff to achieve the positioning of monitoring the status of assets and location of the possibility of staff to grasp the details of the use of assets at all times, to avoid the information asymmetry caused by the assets can not be used, causing greater losses.

Through the use of RFID solutions, the oil field on the asset management efficiency greatly improved, and access to data more accurate than ever before, the relevant responsible person said: "compared to the past management, RFID benefits are very satisfactory , If large-scale applications, will greatly reduce the annual oilfield asset management costs. "

Highlights of this application case:

Scale: Sinopec Oil field to all types of assets to install all the labels, to achieve a systematic management; and plans within the next few years on a variety of types of asset equipment to expand RFID applications.

ROI: Oilfields are costly in terms of asset management every year. By using RFID, not only improves asset management efficiency, but also greatly reduces management costs by increasing the utilization of asset equipment.

Representation: Oil and gas development has always been at the forefront of RFID applications and is well suited for RFID technology applications. significance.

Cellphone:

+86-13606915775(John Lee)

Phone:

+86-592-3365735(John)

+86-592-3365675(Cathy)

+86-592-3166853(Margaret)

+86-592-3365715(Anna)

+86-592-3365685(Ellen)

+86-592-3365681(Lynne)

Add: No.943, Tonglong Er Lu, Hongtang Town, Tong'an District, Xiamen( Xminnov IOT Industrial Park)